Understanding Dewatering and Its Importance

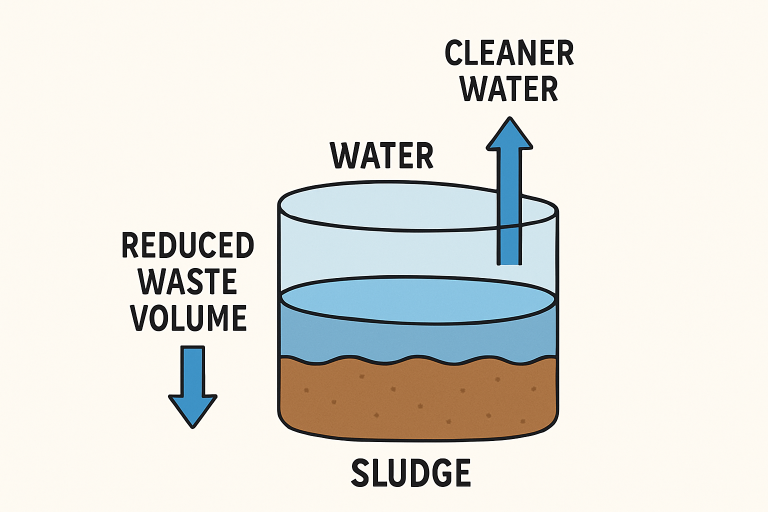

Dewatering is indispensable across several industries, notably in wastewater treatment, mining, food processing, and construction. The core objective of dewatering is to efficiently separate water from solids, significantly reducing the volume of waste that must be handled, transported, and disposed of. This leads directly to lower disposal costs and helps facilities comply with environmental regulations.

For organizations seeking scalable solutions, sludge dewatering equipment rental offers flexibility to match fluctuating processing needs without the upfront investment in permanent machinery. Efficient dewatering minimizes environmental impact, streamlines operations, and increases profitability.

Implementing Advanced Dewatering Technologies

Embracing the latest advancements in dewatering technology can transform operational workflows and performance outcomes. Multi-plate screw presses, for example, leverage slow-rotating screws and interleaving plates to compress and dewater sludge more effectively than conventional methods. These presses regularly achieve solids content as high as 15-20%, slashing sludge volume by up to 80%. Such reductions lead to substantial savings in transportation and landfill costs, aligned with stricter environmental requirements.

According to the U.S. Environmental Protection Agency, integrating advanced dosing and pressurization systems can further optimize water separation, minimize backflow, and extend the lifespan of dewatering infrastructure.

Optimizing Operational Parameters

Carefully tuning operational variables is critical to achieving the highest dewatering efficiency. Fundamental parameters such as feed rate, pressure application, and cycle times must be calibrated to match the volume and characteristics of the incoming sludge. Digital control systems and intelligent automation platforms empower facilities to make real-time adjustments, responding instantaneously to fluctuations in flow, viscosity, or particle size.

Data-driven monitoring and feedback cut energy consumption, reduce operator error, and increase throughput and product consistency. These improvements translate into noticeable cost savings and more reliable compliance with tightening water quality standards.

Enhancing Sludge Conditioning

Effective sludge conditioning is a foundational step that sets the stage for successful dewatering downstream. Homogenization, thermal conditioning, or chemical dosing stabilizes the sludge and produces a uniform, pumpable mixture. Mechanical macerators—devices like the RotaCut—use precision-cutting action to break down fibrous materials and produce a consistent slurry. This pre-treatment is vital for achieving drier cakes, higher solids capture rates, and lower post-dewatering disposal expenses.

Uniform conditioned sludge improves the performance of presses and centrifuges and minimizes wear and tear, prolonging the service life of dewatering equipment.

Regular Maintenance and Equipment Upgrades

Staying proactive with regular maintenance is essential to maximizing uptime, maintaining performance, and averting costly equipment failures. Scheduled inspections allow operators to identify early signs of wear, clogging, or calibration drift—enabling prompt intervention before these issues escalate.

Timely upgrades to contemporary systems featuring automated controls, improved materials, and advanced sensors can yield significant long-term benefits. Facilities that modernize their equipment stand to gain from greater efficiency, reduced manual oversight, and higher reliability, ensuring consistent compliance with environmental standards and reducing the total cost of ownership.

Training and Skilled Personnel

Operator expertise is a decisive factor in achieving and sustaining optimal dewatering results. Comprehensive training programs covering system operation, preventive maintenance, troubleshooting, and safety empower staff to respond quickly to process disruptions and minimize operational errors. Well-trained teams foster a culture of continuous improvement and innovation, ensuring best practices are observed across all shifts and scenarios.

Additionally, investment in staff development improves job satisfaction and retention, contributing to smoother and more resilient operations even as technologies evolve.

Utilizing Superabsorbent Polymers

Superabsorbent polymers (SAPs) offer a cutting-edge solution for accelerating solid-liquid separation in waste management. When added to liquid-bearing waste, SAPs quickly absorb immense quantities of water and convert it to a stable gel, reducing handling time and enhancing the subsequent dewatering equipment’s efficiency.

This approach is gaining momentum due to its ability to expedite treatment, lower overall costs, and produce drier final solids. SAPs are especially effective for waste streams with fluctuating liquid content or challenging-to-treat residues, making them a versatile option for diverse industrial applications.

Monitoring and Automation

Adopting advanced monitoring systems and automation is reshaping the landscape of dewatering performance. Sensors that track moisture content, sludge thickness, and flow rates enable process parameters to be continuously monitored and instantly adjusted. This level of precision minimizes downtime, enhances system reliability, and ensures consistent output quality regardless of variations in input material or external conditions.

Automation also reduces the labor burden, streamlines reporting, and helps establish robust record-keeping for regulatory or internal performance assessments.

Final Thoughts

Achieving peak dewatering performance while minimizing waste volume demands a cohesive strategy that unites advanced technologies, optimized operational variables, rigorous maintenance, skilled personnel, and innovative materials. Investments in automation and real-time monitoring further future-proof operations, delivering ongoing improvements in efficiency and cost-effectiveness. By implementing these proven strategies, industries can realize immediate gains in productivity and savings and support broader goals of environmental stewardship and regulatory compliance.